R-Tech Plasma Cutting Support & Information

Plasma Cutting Videos

Plasma Cutting FAQs

-

How does Plasma Cutting compare to Oxy-Acetelyne?

Plasma cutting has many benefits over oxy-acetelyne cutting

- Produces much cleaner cuts with minimal or no cleaning up required after cut

- It only requires compressed air and a power supply - no more costly gas bottles

- Our Plasma Cutters are easily manoeuvrable and feature a long metre cutting torch, no more heavy gas bottles to lug around - Health & Safety friendly

- Produces much cleaner cuts with minimal or no cleaning up required after cut

-

What metals can you cut with a Plasma Cutter?

You can cut any electrically conductive material with a Plasma Cutter, including steel, stainless steel, copper and aluminium.

You will get a very clean cut on steels, so generally ready to weld once you have removed the dross which will easily snap off with a pair of pliers.

Aluminium as it is softer with produce a more rough edge of cut that would need cleaning up.

Plasma cutters state cut depth on steel, for harder steels and aluminium the maximum cut dept is generally reduced by about 25% -

How to cut circles with a plasma cutting circle kit

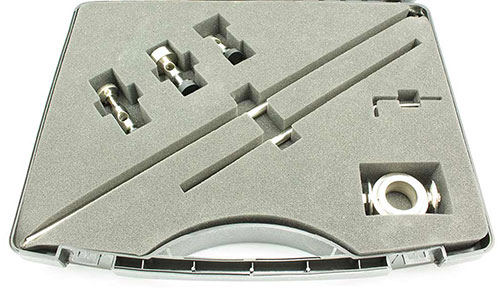

You can easily cut perfect circles using a circle cutting kit.

For our P51D and I-Cut100 Plasma cutters the kit comprises of a 2 wheel guide that attaches to the head of the plasma cutter which incorporates a bearing, so the head can rotate in the guide. You then have extension bars which screw into the head guide and into the centre of the hole holder which can be magnetic, secured via a drilled hole or a small indent in work. These will generally cut circles from 70mm to 800mm.

For our P30C and P31C Plasma Cutters. the circle kit supplied with 2 wheel guide to hold torch head and 1 bar and centre pivot, this will cut between 8CM and 85CM circles.

-

How do you setup a Plasma Cutter?

Setting up a plasma cutter is very easy. Once you have the machine package, air comrpessor and air hose just follow the steps below.

7 Easy Steps To Set Up A Plasma Cutter:

Step 1) Connect your plasma cutter to a suitable air compressor using PCL quick fitting on rear of machine.

Step 2) Connect your plasma cutter to a 240V or 415V supply (depending on the machine purchased).

Step 3) Connect the earth lead to your workpiece.

Step 4) Connect your plasma cutting torch to the plasma cutting machine.

Step 5) Select your cutting amperage (more amps for thicker materials).

Step 6) Set the air pressure using adjusting knob on air pressure regulator on machine as shown in manual. Your are now ready to start cutting.

Step 7) Press the switch on your torch handle and move the torch across the work as the plasma arc cuts the metal.

You generally start from the edge of work or can pierce a hole in the middle of the metal. You can also cut perfect circles with a circle cutting kit and make unique shapes using a template.

As there are no heavy gas bottles to lug around, plasma cutters are fairly portable and the minimized heat affected zone with small cut width compared to oxy-fuel cutting is a great benefit. -

Do your plasma cutters really produce clean cuts as you state?

Simply, the honest answer is yes! We specify the genuine clean cut and severance cut, some manufacturers only state maximum cut which is severance cut.

Clean cut is exactly as is states, once you have finished your plasma cutting you may be left with some slag at bottom of cut, this will simply break off with a pair of pliers. The cut metal is then ready for use does not require any cleaning up.

Severance cut means the maximum cut you will get, you will experience some distortion to the cut face at the bottom on a severance cut. It will be a clean cut to the genuine stated clean cut depth, past that it will be distorted and may require some cleaning up.

The cut depths on our R-Tech range of Plasma Cutters are as follows- Plasma 31C, Clean Cut 8mm, Severance Cut 12mm

- Plasma P51D, Clean Cut 20mm, Severance Cut 24mm

- I-CUT100, Clean Cut 32mm, Severance Cut 40mm

-

Whats the difference between a clean cut and severance cut?

Clean Cut

A Clean Cut is where the machine will cut all the way through the material and the cut parts will fall away from each other leaving only minimal dross on the bottom edge which can easily be pulled off using pliers etc.

The cutting marks will start off straight and then give a slope of a small angle towards the bottom of the cut. The metal should require no extra working before being welded together etc.

Severance Cut

A Severance Cut is where the user is using the machine close to its maximum cutting thickness capability. The cutting speed will be much slower compared to a clean cut and the metal will require some cleaning up towards the bottom edge. -

Which Plasma Cutting Machine Do I Need?

First, you must find yourself the answers to the below questions:

- What input voltage do you have in your workshop, 240V or 415V?

- What is the maximum thickness of the metal you want to cut?

- Do you have a supply of compressed air? (You will need an air compressor to supply compressed air to the plasma cutter.)

Second, have a look at which one of R-Tech's Plasma Cutters is suitable for your needs:

Our R-Tech P31C plasma cutter requires a 240V 13A supply so is very portable and suitable for DIY & light industrial use. It has an automatic cutting start via HF contact start. It features an 8mm clean cut and 12mm severance cut on mild steel.

Our R-Tech P51D plasma cutter requires a 240V 32A supply which is generally found in most workshop environments. It has automatic cut starting via pilot arc starting with auto-restart and features a generous 20mm clean cut and 24mm severance cut on mild steel.

Our R-Tech I-Cut100 plasma cutter requires a 415V 3-phase 22A supply which is found in industrial workshops. It has automatic cut starting via HF pilot arc starting with auto-restart and features a massive 32mm clean cut and 40mm severance cut. -

How do I ensure correct plasma cutting speed and amperage?

Your cutting speed when plasma cutting is dictated by the amperage used and the thickness / type of the material to be cut.

If you are cutting 4mm with a 30A machine, you could either set the amperage to 20A and have a medium travel speed, or you could set the machine to maximum 30A (which will cut 8mm clean) and enjoy a faster travel speed, however you may experience slightly more dross at the bottom of the cut this way.

It also depends on finish required, for salvage when cutting up for scrap you may turn machine to its maximum power and cut very quickly as you are not too fussed on the finish.

What happens if you cut too slow?

If you cut too slow you may experience the arc cutting out with a contact start HF machine, or if using a pilot arc machine, it may start to splutter (going between pilot arc and main cutting power) as it has run out of material to cut. You will also get heat input into work and experience more dross at the bottom of cut - so increase your travel speed or reduce cutting amperage.

What happens if you cut too fast?

If you cut too fast you will experience two things:

Poor cut quality. As you have not cut all the way through the material it will not break away from each other at the end of the cut, and it will require a lot of cleaning up before use.

The blowback of dross. As you have not cut all the way through and have moved the torch, the dross (cut metal) will not be able to blow out the bottom, so it will blow at a severe angle at the bottom and if you are moving far too fast, it will blow back towards the operator.

How to tell if you're cutting at the right speed.

When starting from the edge of the work ensure the metal has been cut through and the dross is coming out the bottom at a maximum of a 10-20 degree angle. Then start moving the torch along the work ensuring the dross angle does not increase.

If the angle of dross starts to increase close to a 45-degree angle, slow down the cutting speed as you haven't fully cut the metal. If you struggle to get a good clean cut and have a small angle of dross coming out the bottom, try increasing the cutting amperage -

What air compressor Is required for Plasma Cutting?

You must select a suitable air compressor to be able to supply the correct amount of air flow to your plasma cutter. Using too small an air compressor will result in the air compressor running all the time, and also the lack of correct air pressure to the plasma cutter will result in a poor consistent cut.

For our R-Tech plasma cutting machines, we recommend the following air compressors as a minimum to achieve good cutting results:

P30C, P31C, P50HF and P51D Plasma Cutters: 3HP 50L Air Compressor as a minimum, if you are doing a lot of long cuts we would suggest a 100L compressor.

I-Cut100P Plasma Cutter: A 3HP 100L Air Compressor.

All plasma cutters require a clean dry compressed air supply. Ensure your air compressor is drained regularly.

All our plasma cutters come fitted with an air pressure regulator with a water trap on the rear of the machine.

If this water trap has signs of water, drain the water trap and air compressor more often or fit an in-line compressed air dryer like our AT1000 Compressed Air Dryer below - The AT1000 can filter up to 1250 litres/minute without any pressure reduction with a degree of filtration .01µinch – 0.25µm

-

What Is gouging when using A plasma cutter?

Gouging is used when you may want to remove an old weld or defect in metal and is suited to machines with pilot arc starting like our P51D and I-CUT100. You will need to use a special gouging tip which has a much larger hole than a standard cutting tip.

You hold the torch at about 45 degrees to work and adjust arc length (the distance between the cutting tip and metal) and speed to blow away unwanted metal.

Please note:

- Do not attempt to gouge too much at one time, multiple passes may be required.

- Be aware that sparks/dross will be generated in this process and to guide dross away from torch/user and take care with other staff in the cutting area. -

What is the difference from HF contact start and Pilot Arc start

All our R-Tech Plasma Cutters feature automatic arc starting - This comes in 2 different styles.

Contact HF starting as found on our P30C & PC31 Plasma Cutters, uses HF to jump the gap between the torch tip and workpiece when the trigger is pressed and tip is held on work surface.

Once the arc has started the HF turns off automatically. This will start on lightly painted and rusty surfaces with ease. If the surface has a very heavy coat of paint, you may need to grind this of if cutting is difficult to start.

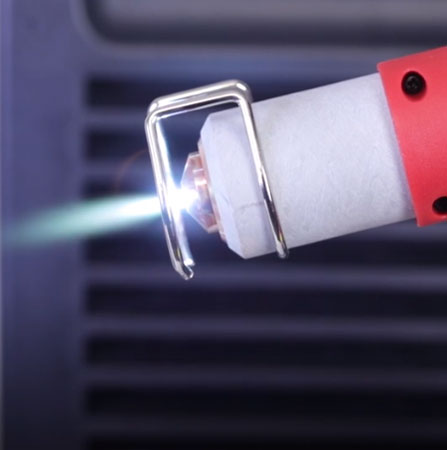

Pilot ARC starting as found on our P51D and I-Cut100 start a pilot arc. A 1-inch blue flame comes from end of torch when trigger is pressed - when this arc touches the workpiece, the machine senses a circuit and then turns on the main cutting power - The pilot arc is very strong and can cut 2mm into steel so this is ideal for starting on very painted surfaces.

Pilot ARC re-starting as found on our P51D and I-Cut100 machines is where the machine senses no more metal to cut, so re-establishes the pilot arc until more metal is sensed, ideal for cutting mesh etc. -

I have a P50HF and see you fitted two torches AG60 and LT70 , how do I ensure I order the correct consumables.

We currently supply the LT70 torch with our P50HF Plasma Cutter, previsouly we supplied it with an AG60 torch.

So how can you tell the difference? The model number is shown on the torch head/handle, if this has come off / worn away use the following.AG60 torch has a pink outer ceramic and a silver coloured contact tip and electrode.

LT70 torch has a grey/silver out nozzle and a copper coloured cutting tip and electrode.

See the AG60 Plasma Torch consumables here