New R-Tech Digital AC/DC TIG Welders

We are proud to showcase our most advanced range of AC/DC TIG Welders to date.

Introducing our brand new Range of DIGITAL AC/DC TIG Welders

Our ever popular EXT range of TIG Welding Machines have been on the market since 2014, and have always included many advanced features as part of the build, perhaps leading you to wonder if our Machines could get any better.

Well, with the TFT range of AC/DC TIG Welders , we have moved the game on.

So what’s new?

This brand new range of AC/DC TIG WELDERS embraces new technology, and incorporates many settings and features, never seen before on our TIG Welding Machines, including:

Large 5.1 inch HD Display Screen

The new Full Colour HD Display Screen is included on every Machine in this range, allowing you to see every setting clearly displayed and easily changed.

R-Tech Easy Setup

With our brand new R-Tech Easy setup we have built in over 220 professional weld settings for you, taking all of the guesswork out of setting your Machine up.

With this intelligent feature all you need to do is select or change the following parameters:

- Weld type (DC, AC , DC MMA, AC MMA)

- Tungsten Size

- Material Thickness

- Material Type

- Joint Type

- Pulse Level

- Control Option

All this is done on a single menu screen, there is no scrolling required, and it is fast and effective. Once you have entered these settings, the Machine will set the amperage required for your weld, along with recommending Gas flow and Cup size.

Alongside this, if full control is what you want, you can set the Machine into manual mode, allowing you to take full control of the process and infinitely adjust each setting, of which there are many!

Photo Credit Overkill Performance

Spot and Tack Mode

TACK welding allows you to produce one single fast tack weld for a selected short time when the trigger is pressed.

You can also set a stitch time in this process. This will then set a delay time after the first tack, and then another tack weld will be produced. This will be repeated for as long as the trigger is held down

SPOT welding allows you to produce one single spot weld for a selected time when the trigger is pressed.

You can also set a stitch time in this process.

This will then set a delay time after the first spot, following which another spot weld be started. This will be repeated for along as the trigger is held down.

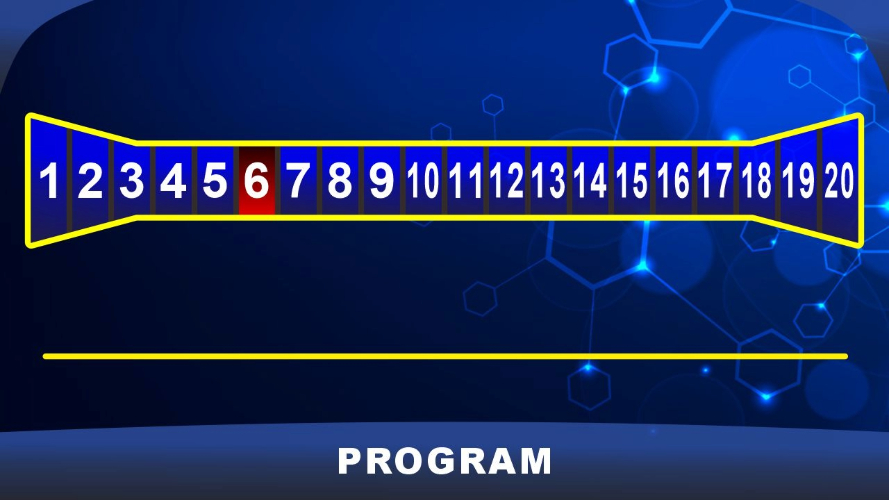

20 Job Memory Storage

A popular feature on our EXT range of AC/DC TIG WELDERS was the memory store function which allowed you to save up to 9 settings, a fantastic feature for saving time when setting up.

With our new Digital AC/DC TIG Welders, we have upgraded the memory function capacity from 9 to an incredible 20!

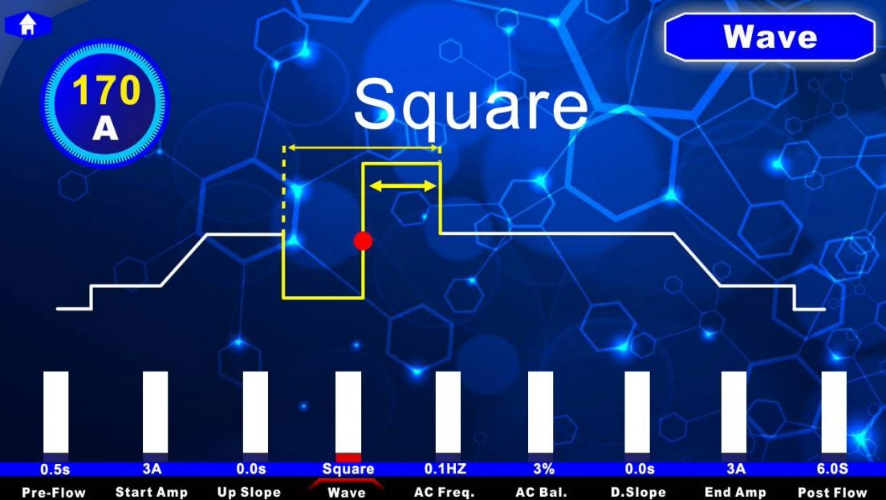

5 Waveforms

- Advanced Square Wave: fast cooling weld pool, deep penetration and fast travel speed

- Soft Square and Sine Wave: Lower arc noise, for a more traditional arc

- Triangular Wave: designed for thin alloys, reduces heat input

- Trapezoidal Wave: Giving the ultimate control of weld pool and bead

Want to learn more?

Checkout these videos on our new Range of Digital TIG Welders below: