Lets Talk Gasless Welding

When considering a new welder, you may have encountered other manufacturers promoting a gasless MIG welder that "eliminates the need for gas." Sounds great, right?

What is Gasless MIG Welding and how does it work?

Gasless MIG Welding is the process of welding pieces of material together using what is called Flux cored wire (Gasless MIG Wire).

Traditionally when MIG Welding, you would use a shielding gas such as Argon Co2 along with your copper coated welding wire, whereas when using gasless welding wire, the flux on the wire produces its own shielding gas creating the arc between the wire and the material.

This process is very similar to that of ARC (MMA) Welding but in a more controllable MIG form.

How to Weld using Gasless Wire

All R-Tech MIG welders can be utilized with shielding gas or gasless wire.

When using your R-Tech MIG Welder with gasless MIG wire, the process is simple!

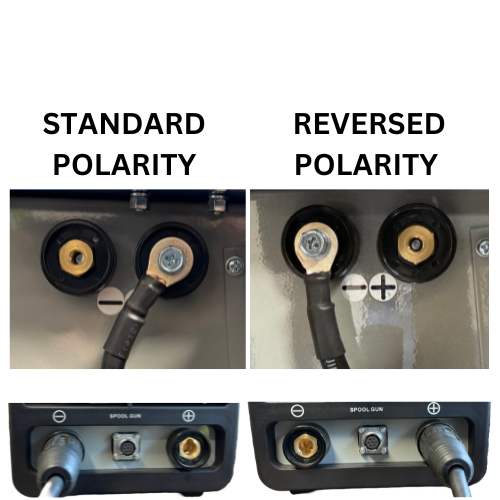

Just install the flux cored gasless wire, switch the machine's polarity (refer to the instructional image below), attach the correct tip size (typically 0.8mm), adjust your volts and wire speed, and you're ready to start your welding project!

To make it even easier, with our new range of digital MIG welders, we have installed a gasless wire option on our easy set settings.

Simply tell the Machine what the thickness of wire and material is, and the Machine will do the rest!

Some welders may suggest using a contact tip larger than the thickness of the wire being used and installing what is called a knurled roller. However, in our experience, when being used with our machines, this is not necessary.

What is Gasless MIG good for and why would you use it?

The main advantage of using gasless welding and what people find most attractive is the portability of the setup.

Since you don't need to use gas, you won't have to carry around an argon gas bottle. You can simply plug in and start welding.

This method is excellent for outdoor work because unlike gas shielded wire, the argon gas won't be blown away in the wind.

Gasless wire welding does have its pros and cons though..

While it produces structurally strong welds, it runs very hot due to the flux and can be quite spattery, potentially creating a right mess if not used correctly.

Would I use gasless wire on my car? Absolutely not!

However, it is excellent for thicker, structural welds that need to be strong but not necessarily aesthetically pleasing. For example, if your gate post at the bottom of your garden is broken and needs repair, gasless wire welding is perfect for this task!

It is strong and will effectively re-join the broken pieces together.

So to round up, does gasless wire eliminate the need for MIG gas? No, but it does have its place in the welding world.

When used properly, it can offer great portability and create strong welds for.

And if you do come across a ''Gasless MIG Welding Machine'' that claims to be great for everything including your car, and will completely eliminate the need for gas, don't say we didn't warn ya!