GET- Open new school in The Forest of Dean

GET are proud to announce that their new engineering school in The Forest of Dean is now open!

GET have been providing work-based learning in engineering for over 40 years!

They train apprentices in Mechanical, Electrical, Maintenance, Welding & Fabrication and also offer dual skill programs for those employers who require multiskilled individuals.

We of course take great pride in assisting businesses teach the next generation the vital skills of Welding and Engineering.

We have been working with Gloucestershire engineering training (GET) for many years now, supplying their training facility over in Gloucestershire with Welding Machines, Equipment and everything in between.

If you’re an avid reader of our Blog pieces, you will recognise Gloucestershire Engineering Training from our meet the welder piece on (now) Senior Instructor and welding guru Paul Smith.

In this blog we travelled over to see Jake Weatherly at their brand new learning facility in the Forest of dean.

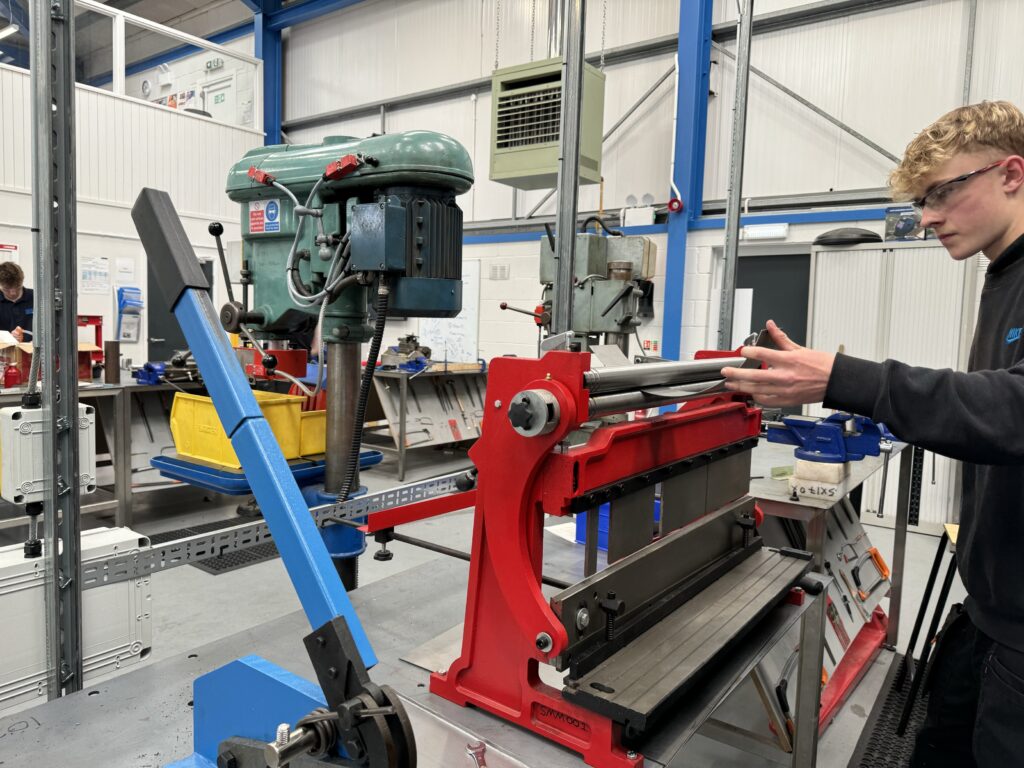

This shiny new facility is the latest addition from GET to cater to more young people within the Gloucestershire area who are interested in engineering as a career path.

We caught up with Jake to get an insight on the newest addition to GET

Who are you and what do you do at GET?

My name is Jake Weatherley, I’m the Training and Maintenance manager for Gloucestershire Engineering Training. I manage our commercial based skills training courses and NVQ delivery as well as the Maintenance team that looks after our machinery and facilities across our two sites.

Tell us a bit about the new School

GET is a private training provider that has been working with industry employer partners across Gloucestershire for 47 years.

Our main site is located in Barnwood Gloucester, and we have opened up our new training centre in Cinderford in the Forest of Dean. We have set up the school to deliver first year foundation training to engineering apprentices as well as commercial based training for local employers.

What Machines do you have setup at the school?

We have setup the center with 5 Mills, 5 Lathes, a CNC Mill and Lathe, a welding and fabrication cell, fitting and maintenance cell and an Electrical/ Electronic workshop.

This is to meet the needs of the wide range of apprenticeship standards we deliver and our commercial skills offering.

What R-Tech Equipment Do You Use? What Do You Like About It?

We have set up 4 welding bays at the new center, replicating our set up of 5 bays in Gloucester.

We have kitted each bay out with an R-Tech 250 Amp MIG Welder and a TIG 201 AC/DC TIG Welders welding plant.

The R-Tech 250 Amp MIG Welder is perfect for us, and it gives us capability to weld steel from 1mm thick right the way up to 12mm.

This flexibility is critical for us when tailoring our welding courses to meet employer needs.

The TIG 201 AC/DC Tig Welder again gives us flexibility to offer welding of mild steel, Aluminum and stainless, critical for us meeting the needs of local aerospace and food manufacturing employers.

The analogue dials are a massive benefit for us also, allowing our instructors and learners to quickly adjust the parameters mid-weld so that we can see the effects of voltage and current on the weld.

What made you guys open another school up and why did you choose the location?

We have opened the new training centre in the Forest of Dean to better support learners with the logistical and transportation barriers that they face commuting from the Forest to the surrounding cities for engineering Training provision. This also opens the door for employers to access local training for upskilling existing staff.

We take on around 125 new apprentices each year across our level 3 and level 4 programs and see approximately 15 percent of these from the Forest. There is strong engineering heritage in the Forest of Dean with many engineering companies operating today. This training center will greatly support the local industry needs, existing apprentices and open up engineering as an opportunity to many more. We opened the center in Cinderford as this is the center of the Forest of Dean providing strong public transport links to the surrounding towns and villages.

What’s Most Rewarding About Your Work?

The most rewarding part of the job is being able to pass on your own skills and knowledge to support someone’s development within their career path, whether it is an apprentice at the start of their career or an existing employee being upskilled on one of our courses. We work closely with our employers and support apprentices progress from day one of the apprenticeship right up to their completion and progression beyond, seeing how people develop and progress over this time period always gives great reward to our staff.

How Do You See The Future Of Welding?

As engineering and manufacturing evolves and innovates towards automation, we see that there is always going to be a need and reliance for the traditional manual welding skills and knowledge.

We see first hand the skills gap within the engineering industry, particularly within welding and fabrication. Many employers are identifying this gap within their workforce and investing in upskilling of existing staff or recruitment of apprentices to bring welding skills back in house to support manufacturing and maintenance needs