AC/DC TIG Welder, Digital or Analogue?

What is TIG Welding?

TIG Welding can be used to weld aluminium, copper, titanium and even two dissimilar metals. This process is ideally suited to handling tricky welds such as S-Shapes, curves, corners or where the weld is going to be visible and where accuracy and finish is important. TIG welding allows a greater variety of metals to be welded than other forms of welding

As technology has evolved, so has the AC/DC TIG Welder. It would be a rare sight to now see an AC/DC welder running on old transformers, however can't be missed due to the size of them! With new IGBT Inverter technology the machines got smaller, lighter, and much more portable. However, a new change is sweeping through the welding industry in the form of how we set up our AC/DC TIG Welder but does this make the analogue machine a thing of the past?.

Difference Between Analogue & Digital TIG Welders

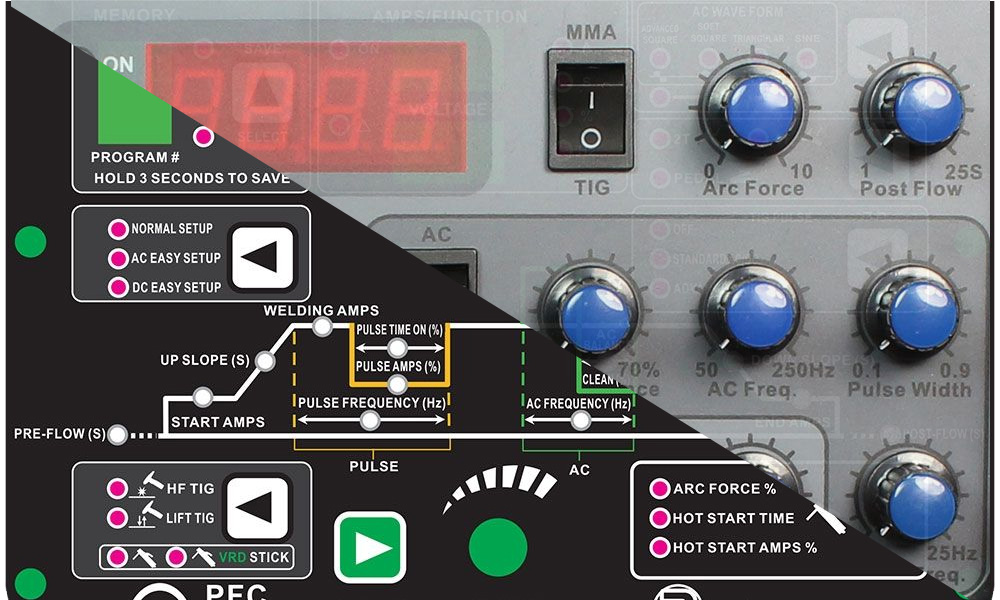

If you're new to the world of welding, you're probably scratching your head wondering what the difference is between analogue and digital. To put it simply, we mainly refer to how we set up our machines, the amps, pulse, upslope, downslope etc. Analogue machines do this by adjusting the individual dials on the front of the machine where as a digital machine does this through one dial and step through process.

What You Get on a Digital Machine.

A TIG 170ext Digital machine will do everything a TIG161ext analogue machine can do in terms of welding capability however they come with extra features to really fine tune your set up and increase productivity. These extra features include the following -

Memory Function.

All digital models come with a 9 job memory function, this allows the user to save multiple pre-sets into the machine. This feature is particularly useful for the welder who finds themselves welding different materials and thicknesses on a continual basis. You simply choose the pre-set you have saved and away you go, no more remembering which position you had a particular dial in.

Easy Setup

By no means does this do all the work when it comes to getting the settings spot on. No machine on the market, be it an R-Tech or another brand will know the quality of the material you are welding, your welding style and the type of weld you will be doing. Easy set up does provide a foundation to which you can tweak and build upon which in turn saves you time and increases efficiency.

Power Factor Correction.

Gives lower running costs, it is a more energy efficient welding machine, cleans noisy power supplies & is 100% generator friendly increasing the portability of the AC/DC TIG Welder.

Lift Start and HF Start

Lift, which also known as scratch, start is a useful feature when welding close to sensitive electrical components such as ECU's, where HF (high frequency) can potentially damage these components.

Lower Range Amperages

Depending on the model of machine, amperages could start as low as 3amps in the DC process and 5 in AC. There isn't much out there which would require you to be welding at these extremely low amperages however, it works particularly well when pulse welding.

Fine Tuning of Settings.

With all digital machines, you can precisely dial in your amperages, pulse settings, slopes and frequencies. This is all displayed on the digital readout located on the machine. With analogue machines, you only have the dials and indicators to rely on.

4 AC Waveforms.

Advanced Square Wave, Soft Square wave, Triangular wave & Sine wave can be selected on the digital machines. By changing the amperage waves, you are changing how the amperages fluctuate and behave during the process. We will go further into which individual wave does, and their benefits in another blog.

Are Digital TIG Welders Worth the Cost?

With the extra features you get considering the price difference between an analogue and digital machine isn't much at all, Yes, a digital machine is definitely worth it! It all depends on what you are going to be doing with the machine. Would the work you are hoping to use the machine for benefit from these additional features? If you're just welding the same thing day in day out then an analogue machine may be the better option.

At the end of the day, it's whichever machine you would be comfortable with using. Welders that have been in the game for a long time would favour the analogue machines over the digital machines as it is what they are used to using, it's simple and effective.